The Effect of Epoxy Injection Molding: Revealing Its Advantages and Versatile Applications

You may be amazed by exactly how epoxy shot molding is transforming different markets. This procedure isn't practically producing solid and light-weight parts; it's also about effectiveness and sustainability. As you explore its applications in fields like vehicle and aerospace, you'll discover fascinating benefits that can alter exactly how products are designed and manufactured. What if these developments could redefine market standards? Allow's reveal the possible with each other.

Comprehending Epoxy Injection Molding

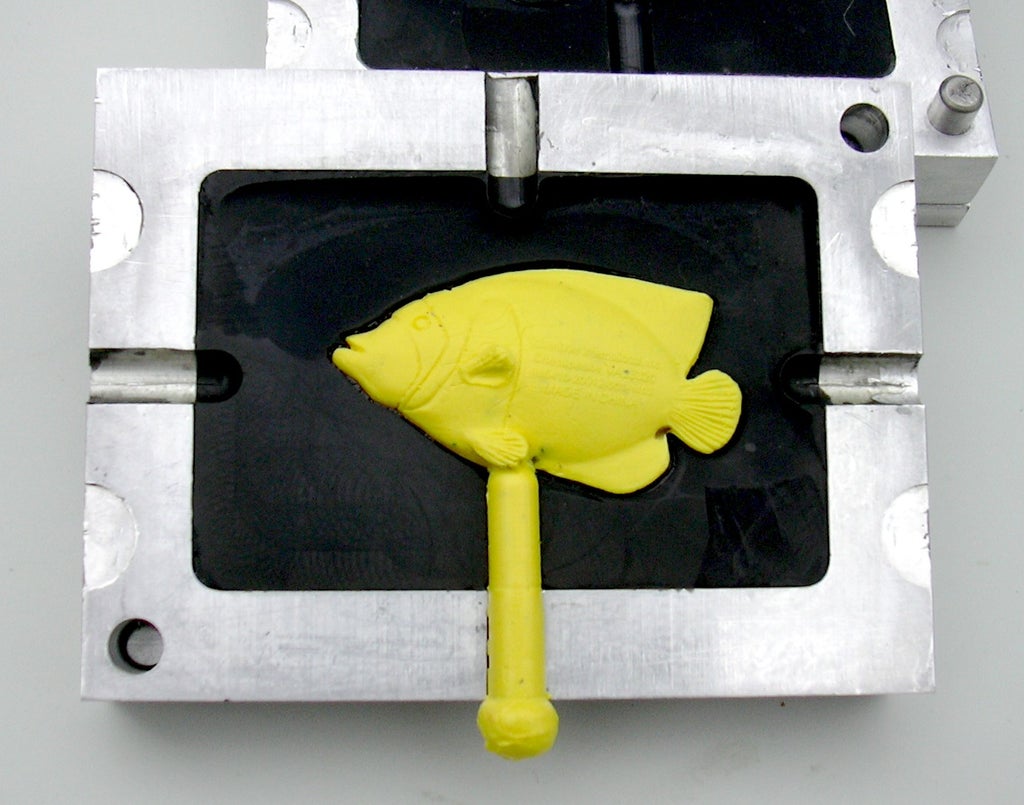

When you consider modern-day manufacturing techniques, epoxy shot molding attracts attention as a functional and efficient process - epoxy injection molding. This technique entails infusing fluid epoxy resin right into a mold and mildew, where it strengthens into a durable part. You'll value how it incorporates the advantages of typical shot molding with the one-of-a-kind buildings of epoxy.Epoxy materials, recognized for their remarkable bond and stamina, allow for the production of elaborate layouts with exceptional surface coatings. As you discover the process, you'll understand it's optimal for creating both big and small amounts of parts, making it cost-effective for different applications.Understanding exactly how epoxy injection molding works can boost your decision-making in product development. Whether you're functioning on automotive components, electronic devices, or durable goods, you'll locate that this strategy satisfies varied production needs while making sure top quality outcomes. Accepting epoxy shot molding can really elevate your manufacturing capacities

Advantages of Epoxy Resins in Manufacturing

You're opting for exceptional toughness and toughness that can hold up against hard problems when you pick epoxy materials for production. Their excellent chemical resistance means your products will hold up against various materials without degrading. Plus, their flexible application variety allows you to utilize them in a wide array of markets, making them a clever choice for your tasks.

Superior Toughness and Toughness

Epoxy materials are understood for their premium durability and stamina, making them a leading option in producing processes. When you choose epoxy, you're choosing materials that can endure high tension and pressure, guaranteeing resilient efficiency. This durability indicates that parts made from epoxy can sustain extreme settings without breaking or damaging. You'll also locate that epoxy's strength-to-weight ratio goes over, permitting lightweight designs without giving up architectural integrity. This is particularly valuable in sectors like automobile and aerospace, where every ounce matters. By integrating epoxy right into your production, you improve the durability and dependability of your items, reducing the requirement for regular replacements and upkeep. Ultimately, this selection results in extra effective and affordable operations.

Exceptional Chemical Resistance

One of the standout functions of epoxy resins is their superb chemical resistance, which makes them excellent for various production applications. You'll find that these materials endure severe chemicals, solvents, and acids without breaking down, making sure durable performance sought after settings. This toughness suggests you can use epoxy in markets such as automotive, aerospace, and electronics, where direct exposure to destructive materials is common. You will not have to stress over premature failure or regular substitutes, which can save you money and time. Plus, the ability to keep structural honesty under chemical stress and anxiety makes epoxy a trustworthy choice for safety finishes and adhesives. With epoxy, you're picking a product that can take care of the toughest obstacles easily.

Flexible Application Variety

Beyond their remarkable chemical resistance, epoxy materials offer a versatile application variety that satisfies countless markets. You'll find these resins in vehicle parts, electronics, and building and construction products, demonstrating their adaptability. In the automotive industry, they're used for light-weight components that boost fuel effectiveness. In electronic devices, epoxy works as an outstanding insulator, securing sensitive parts from moisture and damages. The building sector gain from their use in adhesives and coverings, providing resilience and resistance to harsh conditions. Furthermore, artists and developers utilize epoxy for developing magnificent finishes in furnishings and artwork. With such diverse applications, it's clear that epoxy resins not only meet different manufacturing needs however additionally improve item performance throughout the board.

Applications in the Automotive Industry

Lightweight elements and improved durability are essential for performance when you assume about the automobile sector. Epoxy shot molding plays an essential function in producing these parts, offering a strong yet light-weight remedy. By leveraging this innovation, you can significantly boost automobile efficiency and long life.

Lightweight Component Production

Lightweight component manufacturing is changing the automotive industry by enhancing gas performance and efficiency. By utilizing epoxy injection molding, you can create parts that are not just lighter yet additionally maintain architectural honesty. These parts help in reducing the general weight of automobiles, resulting in lower fuel intake and reduced emissions. You'll find that lighter cars can speed up faster and handle far better, enhancing the driving experience. In addition, this technique allows more design freedom, permitting innovative shapes and setups that traditional products can't accomplish. As manufacturers accept these lightweight solutions, you're likely to see a shift in vehicle layout, focusing on performance without giving up quality. Ultimately, lightweight production is setting a brand-new standard for vehicle excellence.

Boosted Sturdiness Features

As automobile producers significantly turn to epoxy injection molding, they're discovering significant enhancements in the durability of their parts. This procedure produces components that resist extreme temperatures, wetness, and chemicals, guaranteeing they can hold up against harsh driving conditions. You'll find that these sturdy elements not just enhance the lifespan of lorries yet also minimize maintenance prices for consumers. Epoxy shot molding supplies superb impact resistance, protecting vital parts from damages throughout crashes or harsh surface. Furthermore, the light-weight nature of these parts aids improve fuel performance without jeopardizing toughness. By adopting this ingenious approach, makers are able to offer safer and a lot more reputable lorries, boosting general client complete satisfaction and solidifying their competitive side in the automotive market.

Usage Cases in Aerospace and Defense

Provided the rigorous needs of the aerospace and defense markets, epoxy shot molding confirms important for creating components that hold up against severe conditions. You'll find this innovation is crucial in creating lightweight yet durable parts, such as architectural parts in airplane and army vehicles. The ability to mold and mildew complicated forms enables ingenious you can check here layouts that boost wind resistant performance and decrease weight without jeopardizing strength.Moreover, epoxy injection molding's resistance to severe chemicals and temperature fluctuations makes it excellent for mission-critical applications. You could experience it in the manufacturing of fuel containers, insulation systems, and protective cases for sensitive instruments.Additionally, this process allows rapid prototyping, allowing developers to promptly repeat and examine new principles. By leveraging epoxy injection molding, you guarantee that your aerospace and protection tasks satisfy extensive requirements while gaining from economical manufacturing approaches. Embracing this innovation can considerably improve your capabilities in these requiring industries.

Epoxy Injection Molding in Electronics

While the need for miniaturization and performance in electronic devices continues to expand, epoxy injection molding sticks out as an essential manufacturing procedure. This method enables you to create complex elements with high precision, ensuring that also the smallest electronic tools preserve peak capability. With its excellent thermal stability and electrical protecting residential properties, epoxy is excellent for useful reference encapsulating sensitive electronic devices, safeguarding them from moisture, dirt, and mechanical stress.Using epoxy injection molding, you can accomplish complicated geometries that standard methods have problem with, improving design versatility. The ability to create light-weight yet durable parts assists reduce general tool weight without sacrificing performance. And also, this method commonly results in reduced production costs as a result of its performance and reduced waste - epoxy injection molding.As you explore choices for your digital applications, consider just how epoxy shot molding can enhance your production process and enhance the top quality of your products. It's a game-changer for the developing electronic devices sector

Effect On Industrial Devices and Machinery

When you consider the needs of commercial devices and machinery, epoxy shot molding verifies to be an essential process that boosts resilience and performance. This technique permits you to develop parts that withstand severe conditions, including high temperature levels, chemicals, and mechanical stress and anxiety. By making use of epoxy material, you're making certain that the components preserve their stability much longer, minimizing the demand for constant replacements.Moreover, epoxy shot molding enables accurate production of intricate forms, which is essential in maximizing the performance of equipment. You'll discover that the premium bond buildings of epoxy improve the total strength of put together components, better boosting discover this info here reliability.In enhancement, the lightweight nature of epoxy products adds to power performance in machinery procedure. By selecting epoxy injection molding, you're spending in a process that not just satisfies the extensive demands of sector but additionally sustains sustainability via lowered waste and extensive devices life expectancies.

Future Fads and Innovations in Epoxy Injection Molding

As the industry progresses, you're likely to see exciting trends and technologies in epoxy shot molding that push the boundaries of what's feasible. One significant trend is the assimilation of clever modern technology, allowing for real-time surveillance and top quality control throughout the molding process. This indicates you can accomplish greater accuracy and decrease waste considerably.Additionally, improvements in environmentally friendly epoxy solutions are emerging, making the procedure more lasting without endangering performance. You're also likely to come across enhanced automation techniques, which streamline production and enhance effectiveness, minimizing lead times.Moreover, as industries require lighter and stronger products, epoxy composites are being customized for details applications, such as aerospace and auto sectors. With these advancements, you're not just equaling the market; you're positioning on your own at the leading edge of a rapidly advancing area, all set to take advantage of new opportunities and provide premium items.

Frequently Asked Inquiries

Exactly How Does Epoxy Shot Molding Contrast to Typical Molding Techniques?

Epoxy injection molding offers better precision and sturdiness compared to conventional approaches. You'll observe improved strength and reduced waste, making it a much more reliable option for intricate layouts and high-performance applications in numerous sectors.

What Precaution Are Needed When Using Epoxy Resins?

When making use of epoxy materials, you must put on safety handwear covers, safety glasses, and a mask. Determine correct ventilation and avoid skin get in touch with. Always review security information sheets to comprehend the specific dangers related to your materials.

Can Epoxy Be Recycled After Shot Molding?

You can not usually recycle epoxy after shot molding as a result of its chemical framework. When cured, it ends up being a thermoset polymer, making it tough to reprocess. Nevertheless, some growths in recycling methods are arising.

What Are the Typical Obstacles in Epoxy Injection Molding?

You'll typically encounter difficulties like achieving correct treating, managing thickness, and avoiding air bubbles during epoxy shot molding. epoxy injection molding. Obtaining the best temperature and pressure is important, as well, to assure a constant and successful molding procedure

How Does Temperature Level Affect Epoxy Treating Throughout Shot Molding?

Temperature considerably affects epoxy treating during injection molding. Higher temperatures quicken the treating process, while reduced temperatures can reduce it down or lead to incomplete curing, influencing the last product's toughness and durability. With its excellent thermal security and electric shielding buildings, epoxy is excellent for enveloping sensitive electronic devices, safeguarding them from wetness, dirt, and mechanical stress.Using epoxy injection molding, you can achieve intricate geometries that traditional methods struggle with, improving style flexibility. Plus, this approach commonly results in reduced production expenses due to its effectiveness and decreased waste.As you check out choices for your electronic applications, consider just how epoxy shot molding can streamline your manufacturing procedure and boost the top quality of your items. When you think about the needs of commercial devices and equipment, epoxy injection molding shows to be an important procedure that enhances sturdiness and efficiency. By utilizing epoxy resin, you're guaranteeing that the parts preserve their stability much longer, minimizing the need for constant replacements.Moreover, epoxy injection molding allows accurate production of complex forms, which is crucial in optimizing the functionality of machinery. You'll find that the premium attachment homes of epoxy improve the general stamina of constructed elements, further improving reliability.In enhancement, the lightweight nature of epoxy products adds to power effectiveness in machinery procedure.